I- What is the supply chain?

The supply chain is the heart of the modern business, playing a vital role in the success of its operations and whose purpose is to have products accessible to customers at the best price.

It has a direct impact on profitability and enables the company to gain a competitive advantage in today’s global market.

It therefore refers to all the functions and processes which aim to optimize the flow of products, information and finances from the purchase of raw materials to the provision of the finished product to consumers.

Moreover, good supply chain management involves coordinating these flows from end to end.

In this sense, the supply chain consists of a network of actors contributing to the development of a good. It encompasses an entire logistical system that ranges from the supply of raw materials to distribution, including the production of goods.

In our modern economy, supply chains are highly complex and involve many producers around the world. This is also the case for multinational companies (MNCs), which operate in several countries and use complex supply chains to manage their activities on a global scale.

II- Characteristics of the supply chain

The proper functioning of the supply chain stipulates the incorporation of a certain number of characteristics, such as :

1- Balance

A supply chain is a succession of coordinated activities over phases that must be well planned, detailed and simplified in order to minimize potential risks.

2- Efficiency

An optimally functioning supply chain is one that allows costs to be reduced while ensuring the proper execution of each phase of the process.

3- Coordination

The multitude of stakeholders in the supply chain, including suppliers, carriers, manufacturers and customers, requires careful coordination to ensure the product reaches the end customer in the best possible conditions.

4- Flexible

The efficient supply chain meets criteria of flexibility and speed in the face of changes in market rhythm in terms of supply and demand or the global impacts that may arise.

5- Transparency

Dynamic communication ensuring a continuous flow of information throughout the process, from procurement to final delivery, is the cornerstone of a well-functioning supply chain.

III- What are the 3 flows of the supply chain?

Supply chain management involves managing, organizing, and coordinating flows and the people involved at each stage, while optimizing processes.

It has 3 distinct components :

1- The physical flow

It is the movement, storage, and delivery of raw materials, products, or merchandise from the initial manufacturing location to the point of sale. This may be a physical store, or the storage location from which the merchandise or product will be sold if the business is online.

It is important to choose logistics transport companies carefully to maintain quality service.

2- The flow of data or information

Feedback helps anticipate potential difficulties and problems that may arise during processes. For example :

- The references of all the products that the company sells;

- Information on all service providers involved in the supply chain;

- The way in which goods are stored and transported from one place to another.

Data sharing is a key element in driving more efficient supply chain operations.

3- The financial flow

Maintaining financial records of procurement operations is essential to understanding how money flows between the service providers involved in this process, ensuring that goods are delivered on time.

Besides, in long supply chains, goods can pass through many countries with different laws and regulations, making supply chain management more complex.

IV- Why is the supply chain crucial for the business?

A well-managed supply chain is a crucial foundation for overall business performance, as it offers many benefits to the health and day-to-day operations of the business and enables :

- Improve communication both internally and with service providers thanks to the excellent circulation of data, allowing the company to carry out useful analyses to predict market trends;

- Contribute to the better management of delivery systems, by reducing the risk of shortages and thus guaranteeing product availability while respecting delivery times to increase customer satisfaction;

- Promote cost reduction through optimized operations management, which results in reduced expenses at every stage of the process, from the purchase of raw materials to the delivery of finished products;

- Identify potential risks that could disrupt the supply chain;

- Contribute significantly to improving the company’s competitiveness.

Thus, the proper functioning of the supply chain allows the customer to be delivered as quickly as possible, and the company to invoice more quickly and therefore improve its cash flow.

V- What are the different stages of the supply chain?

The supply chain includes all the steps necessary to create a product and get it to the customer under pre-agreed conditions.

It involves many actors, resources, activities and technologies, each of which makes a vital contribution at different levels of the process.

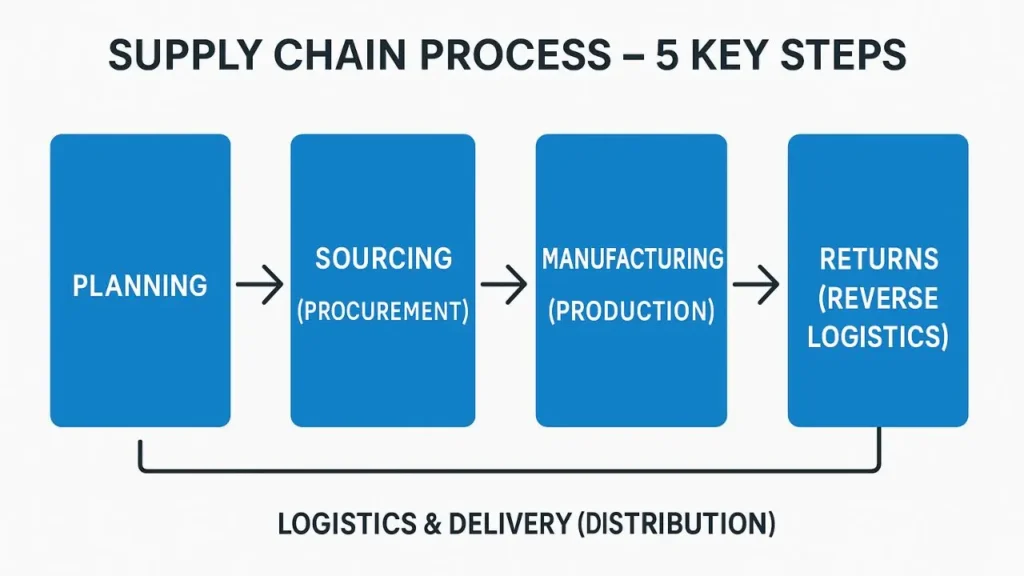

Thus, the five key stages of the supply chain process can be presented as follows :

1- Planning

Optimal supply chain management is based on better planning of operations in two areas :

- Demand forecasting : through the use of historical data and trends to predict future needs andensuring the right products are ready to meet customer demand;

- Resource planning : in order to achieve an optimal allocation of resources to meet expected demand.

Furthermore, the implementation of control tools such as indicators is the ideal strategy to establish solid foundations for measuring whether the supply chain is profitable, efficient and in line with the company’s objectives.

2- Supply

This key step involves selecting suppliers and purchasing quality raw materials. This process includes purchasing and procurement, along with order placement, receiving, and inventory management.

This phase must guarantee two major objectives:

- Inventory management : ensuring a balance between the availability of materials and minimizing storage costs.

- Selection of suppliers : the choice must be made on partners reliable offering the best quality, price and delivery time ratio.

Once the supplier selection process is complete, it’s important to establish management and oversight for this partnership. From order submission to payment and receipt of goods, the process can be optimized for greater efficiency.

3- Production

Being located at the center of the chain, this phase involves the organization of the supply chain operations necessary to accept the raw materials, designad manufacture the product, manage quality control and prepare finished products for shipment.

In general, the two essential levers for improvement to be exploited during this stage are:

- Production management : through monitoring manufacturing processes to ensure quality and efficiency.

- Quality control : the use of product inspection to ensure that they meet established standards is an essential aspect that should not be overlooked.

Effective management of this stage of the process is crucial to ensure product quality and on-time deliveries.

4- Logistics and Delivery

Logistics includes all the elements that enable the supply chain to function.

It begins as soon as the orders are received, followed by transport planning to deliver the product and receive payment.

It has two main bases :

- Transportation : which allows the management of product movements between the different players in the chain ;

- Storage : through the storage of products in such a way as to facilitate their rapid distribution.

This phase involves the precise coordination of orders, planning of transport and delivery times, as well as payment management, ensuring efficient and economical distribution of products to meet real customer needs.

5- Returns

Returns management is the phase of the process that deals with product returns and includes reverse logistics management and refund and satisfaction.

It involves creating an effective protocol or system for recovering defective products, products ordered in error, products chosen incorrectly in size, color, or products that do not meet expectations or are non-compliant.

This stage of the logistics chain plays an important role in both customer satisfaction and company reputation.

Thus, a supply chain is efficient if it makes products and services accessible to customers. To achieve this, it is essential to improve each step of the process to gain efficiency and limit unnecessary expenses.

Conclusion

The supply chain is the central pillar of business performance. Effective management not only reduces costs and improves customer satisfaction, but also strengthens resilience in the face of global challenges. By integrating sustainable practices and advanced technologies, a company can transform its supply chain into a major competitive advantage.

аренда экскаватора-погрузчика аренда экскаватора-погрузчика .

электрокарниз купить в москве электрокарниз купить в москве .

электрокарнизы электрокарнизы .

электрические карнизы купить https://www.karniz-elektroprivodom.ru .

перепланировка нежилого помещения в нежилом здании перепланировка нежилого помещения в нежилом здании .

проект перепланировки нежилого помещения стоимость http://www.pereplanirovka-nezhilogo-pomeshcheniya11.ru .

аренда мини экскаватора в московской области цены http://arenda-mini-ekskavatora-v-moskve-2.ru/ .

проект перепланировки нежилого помещения https://pereplanirovka-nezhilogo-pomeshcheniya9.ru .

стоимость рулонных штор стоимость рулонных штор .

натяжные потолки самара с установкой http://www.natyazhnye-potolki-samara-1.ru .

компания потолочник https://www.stretch-ceilings-samara.ru .

автоматические жалюзи автоматические жалюзи .

потолки самара потолки самара .

потол http://www.natyazhnye-potolki-samara-2.ru/ .

**mind vault**

mind vault is a premium cognitive support formula created for adults 45+. It’s thoughtfully designed to help maintain clear thinking

потолок натяжной потолок натяжной .

натяжные потолки нижний новгород дешево http://www.natyazhnye-potolki-nizhniy-novgorod.ru .

потолочкин натяжные потолки нижний новгород официальный сайт https://www.stretch-ceilings-nizhniy-novgorod.ru .

натяжные потолки в нижнем новгороде натяжные потолки в нижнем новгороде .

кухни под заказ в спб кухни под заказ в спб .

**mind vault**

mind vault is a premium cognitive support formula created for adults 45+. It’s thoughtfully designed to help maintain clear thinking

перепланировка помещений https://soglasovanie-pereplanirovki-kvartiry3.ru .

согласовать проект перепланировки https://soglasovanie-pereplanirovki-kvartiry4.ru .

заказать перепланировку квартиры заказать перепланировку квартиры .

**glpro**

glpro is a natural dietary supplement designed to promote balanced blood sugar levels and curb sugar cravings.

**sugarmute**

sugarmute is a science-guided nutritional supplement created to help maintain balanced blood sugar while supporting steady energy and mental clarity.

**vitta burn**

vitta burn is a liquid dietary supplement formulated to support healthy weight reduction by increasing metabolic rate, reducing hunger, and promoting fat loss.

**synaptigen**

synaptigen is a next-generation brain support supplement that blends natural nootropics, adaptogens

**glucore**

glucore is a nutritional supplement that is given to patients daily to assist in maintaining healthy blood sugar and metabolic rates.

**prodentim**

prodentim an advanced probiotic formulation designed to support exceptional oral hygiene while fortifying teeth and gums.

**nitric boost**

nitric boost is a dietary formula crafted to enhance vitality and promote overall well-being.

**sleep lean**

sleeplean is a US-trusted, naturally focused nighttime support formula that helps your body burn fat while you rest.

**wildgut**

wildgutis a precision-crafted nutritional blend designed to nurture your dog’s digestive tract.

**mitolyn**

mitolyn a nature-inspired supplement crafted to elevate metabolic activity and support sustainable weight management.

**zencortex**

zencortex contains only the natural ingredients that are effective in supporting incredible hearing naturally.

**yu sleep**

yusleep is a gentle, nano-enhanced nightly blend designed to help you drift off quickly, stay asleep longer, and wake feeling clear.

**breathe**

breathe is a plant-powered tincture crafted to promote lung performance and enhance your breathing quality.

**prostadine**

prostadine is a next-generation prostate support formula designed to help maintain, restore, and enhance optimal male prostate performance.

**pinealxt**

pinealxt is a revolutionary supplement that promotes proper pineal gland function and energy levels to support healthy body function.

**energeia**

energeia is the first and only recipe that targets the root cause of stubborn belly fat and Deadly visceral fat.

**prostabliss**

prostabliss is a carefully developed dietary formula aimed at nurturing prostate vitality and improving urinary comfort.

**boostaro**

boostaro is a specially crafted dietary supplement for men who want to elevate their overall health and vitality.

**potentstream**

potentstream is engineered to promote prostate well-being by counteracting the residue that can build up from hard-water minerals within the urinary tract.

проект перепланировки для согласования цена http://proekt-pereplanirovki-kvartiry11.ru/ .

**hepato burn**

hepato burn is a premium nutritional formula designed to enhance liver function, boost metabolism, and support natural fat breakdown.

**hepatoburn**

hepatoburn is a potent, plant-based formula created to promote optimal liver performance and naturally stimulate fat-burning mechanisms.

**flowforce max**

flowforce max delivers a forward-thinking, plant-focused way to support prostate health—while also helping maintain everyday energy, libido, and overall vitality.

**neuro genica**

neuro genica is a dietary supplement formulated to support nerve health and ease discomfort associated with neuropathy.

**cellufend**

cellufend is a natural supplement developed to support balanced blood sugar levels through a blend of botanical extracts and essential nutrients.

**prodentim**

prodentim is a forward-thinking oral wellness blend crafted to nurture and maintain a balanced mouth microbiome.

сео продвижение сайтов топ 10 сео продвижение сайтов топ 10 .

**revitag**

revitag is a daily skin-support formula created to promote a healthy complexion and visibly diminish the appearance of skin tags.

best seo specialists best seo specialists .

агентство по продвижению сайтов агентство по продвижению сайтов .

seo agencies list https://www.reiting-seo-kompaniy.ru .

1 xbet giri? https://1xbet-giris-1.com/ .

xbet xbet .

birxbet birxbet .

birxbet 1xbet-4.com .

1 x bet https://1xbet-10.com/ .

1xbet ?yelik 1xbet ?yelik .

кухни спб на заказ http://www.kuhni-spb-2.ru .

1xbet yeni adresi 1xbet yeni adresi .

медицинские приборы http://medicinskoe–oborudovanie.ru .

наркология москва наркология москва .

наркологическая клиника москва наркологическая клиника москва .

melbet melbet .

статьи про seo статьи про seo .

seo онлайн seo онлайн .

электрокарниз двухрядный цена https://elektrokarniz797.ru .

онлайн трансляции мероприятий онлайн трансляции мероприятий .

организация онлайн трансляции москва организация онлайн трансляции москва .

рейтинг агентств digital маркетинга http://luchshie-digital-agencstva.ru/ .

1xbet giri? yapam?yorum http://1xbet-giris-6.com .

стоимость услуг экскаватора погрузчика стоимость услуг экскаватора погрузчика .

вебинарная студия http://www.studiya-podkastov-spb4.ru .

рейтинг компаний по продвижению сайтов рейтинг компаний по продвижению сайтов .

Your article helped me a lot, is there any more related content? Thanks! https://accounts.binance.info/fr-AF/register-person?ref=JHQQKNKN

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article. https://www.binance.info/de-CH/register?ref=W0BCQMF1

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me? https://accounts.binance.info/id/register-person?ref=UM6SMJM3

Your point of view caught my eye and was very interesting. Thanks. I have a question for you. https://www.binance.com/register?ref=IXBIAFVY

Everything published made a lot of sense. But, what about this? what if you typed a catchier post title? I ain’t saying your content isn’t good., but what if you added a headline that grabbed folk’s attention? I mean %BLOG_TITLE% is kinda plain. You ought to glance at Yahoo’s front page and note how they create news headlines to get viewers to click. You might add a video or a related pic or two to grab readers interested about what you’ve written. Just my opinion, it could bring your website a little bit more interesting.

byueuropaviagraonline

Avia Masters de BGaming es un juego crash con RTP del 97% donde apuestas desde 0,10€ hasta 1.000€, controlas la velocidad de vuelo de un avion que recoge multiplicadores (hasta x250) mientras evita cohetes que reducen ganancias a la mitad, con el objetivo de aterrizar exitosamente en un portaaviones para cobrar el premio acumulado

https://feg.org.es/

ко ланта ко ланте

Hey just wanted to give you a quick heads up and let you know a few of the pictures aren’t loading properly. I’m not sure why but I think its a linking issue. I’ve tried it in two different web browsers and both show the same results.

byueuropaviagraonline

thank you

купить дешево с доставкой Курьерская служба свежих цветов

вскрытие сейфов Замок сейфа сломался? Содержимое нужно срочно? Вскрытие сейфов с гарантией конфиденциальности и сохранности ценностей.

карта краби с достопримечательностями пеликан краби

https://auto.qa/catalog/

бесплатный мод тикток скачать тик ток бесплатно мод последняя версия

рунетки чат рунетки чат

https://diigo.com/011uacl When I started looking into gas fireplaces, I didn’t expect the market to be this diverse. There are major differences between brands in terms of construction materials, burner systems, and flame presentation. Reading detailed product information and real usage feedback helped me understand what actually matters in the long run — things like ease of maintenance, efficiency, and reliable operation. It’s definitely not something you want to choose purely based on price or visual design alone

работа в корее с проживанием работа хостес реальный опыт

рунетки онлайн рунетки чат

рунетки рунетки чат

Трюмо трехстворчатое зеркало Трюмо с подсветкой для спальни: создайте романтическую атмосферу.

La real adrenalina llega al fin en la fase de aterrizaje: si el aviГіn aterriza correctamente a la base en el portaaviones, te llevas el jackpot; si se estrella, se pierde la inversiГіn. Este sistema de todo o nada hace que cada ronda de esta slot sea una experiencia llena de adrenalina.

https://aviamasters.nom.es/

https://jasonejohnsn.wordpress.com/2026/01/31/finding-peace-in-your-personal-sanctuary-a-guide-to-daily-relaxation/ I was researching different small-scale heating options, and Comfort Glow came up multiple times while reviewing different heaters. What caught my attention is how these heaters are designed for regular household use rather than extreme industrial settings.

Factors such as heat consistency, safety shutoff systems, and quiet operation really matter when a heater is used on a regular basis. It’s interesting to see how some brands focus on simple, practical designs that fit well into normal living spaces instead of adding unnecessary complexity.

https://www.minecraftforum.net/members/CodeInscription

пошив штор Шторы блэкаут на заказ – идеальный выбор для тех, кто ценит комфортный сон и конфиденциальность. Специальная ткань блокирует солнечный свет, создавая полную темноту в помещении.

Howdy superb blog! Does running a blog like this take a great deal of work? I have no understanding of coding but I was hoping to start my own blog soon. Anyways, if you have any ideas or tips for new blog owners please share. I understand this is off topic however I simply needed to ask. Many thanks!

https://share.google/vTJuEXfwZttXnBD1U

http://electrotrade.biz/images/pages/?promokod_240.html